Lorem ipsum dolor sit amet, consectetur adipiscing elit. Sed molestie et velit pulvinar pulvinar. Fusce aliquam luctus elit nec laoreet.

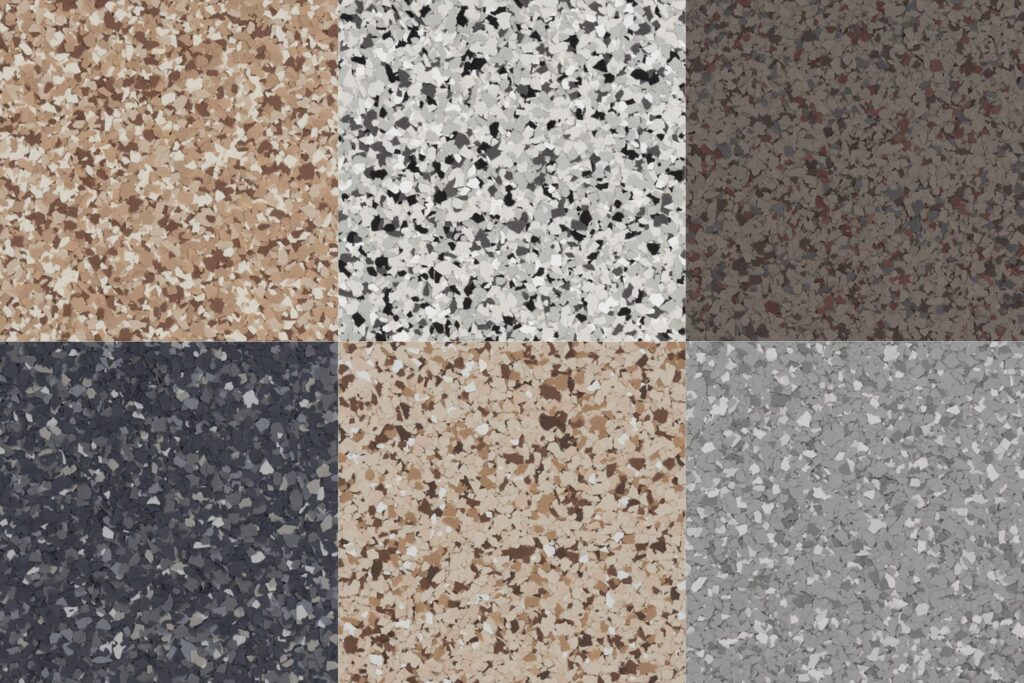

Decorative colored quartz aggregate combined with resins create a unique flooring design while providing a slip-resistant and hard-wearing protective resin floor solution.

The Poly-Crete Systems provide hygienic, chemical and slip-resistant flooring solutions that are extremely hard wearing. The systems are designed for use in industrial and commercial environments such as food and beverage plants, breweries, commercial kitchens, dairies, manufacturing facilities, chemical processing plants, warehouses, garages and more.

Polished concrete floors are a high-quality flooring solution achieved by grinding, honing, and polishing an existing concrete slab to create a sleek, smooth surface. These floors are known for their durability, low-maintenance requirements, and resistance to wear, making them a perfect choice for commercial, industrial, and residential spaces. Whether in warehouses, retail stores, office buildings, restaurants, or modern homes, polished concrete provides a stylish, contemporary look, enhances light reflectivity, and helps lower long-term maintenance costs.

Urethane cement floors are high-performance flooring systems made by combining cement, water, aggregates, and urethane resins. These floors are known for their exceptional durability and resistance to chemicals, thermal shock, and heavy impact, making them ideal for challenging environments. Often used in commercial kitchens, food and beverage processing plants, breweries, pharmaceutical facilities, and industrial warehouses, urethane cement floors offer a seamless, non-porous surface that can endure extreme conditions while meeting hygiene and safety standards.

ESD epoxy floors are specialized coatings designed to control electrostatic discharge, protecting sensitive electronic equipment from damage. These floors provide a conductive surface that safely channels static electricity, making them perfect for environments such as data centers, cleanrooms, and manufacturing facilities.

Epoxy floors are durable and versatile flooring systems created by applying a liquid epoxy resin to a concrete surface, which then hardens into a strong, long-lasting finish. There are various types of epoxy systems available, including flake epoxy, which offers a decorative, textured finish; metallic epoxy, which creates a high-end, reflective appearance; and other specialized epoxy coatings designed for specific needs, such as high-traffic areas or environments requiring additional resistance to chemicals and stains. Epoxy floors are widely used in commercial, industrial, and residential spaces due to their strength, aesthetic appeal, and low-maintenance qualities.

Both epoxy and polyaspartic coatings are great choices for garage floors, but they have key differences:

If installed correctly and with proper care, your new garage epoxy floor can last 10+ years.

Compared to other flooring options, epoxy is extremely easy to clean and maintain. If you follow some basic cleaning schedule and some preventative measurements, you can make sure your epoxy floor is looking like new for longer.

In addition to protecting against color fading, polyurethane UV treatment significantly slows down yellowing and discoloration over time. The main benefit is that it adds an extra layer of protection to your floor, as polyurethane is highly resistant to abrasion, tire marks, and stains, keeping your floors looking new for longer.

The durability of your epoxy or polyaspartic floor depends on how well the concrete is prepared before applying the coating. To ensure the best bond, we diamond grind the surface to remove dirt, oil, and grime while opening the concrete pores. This creates the ideal texture for the coating to adhere properly. Whether your concrete is new or old, grinding is necessary to ensure a lasting, strong bond between the floor and the coating. Proper surface preparation is key to achieving long-term results.

Proper surface preparation is the most important step when applying epoxy, and if not done correctly, your results are likely to fail. While DIY epoxy kits may seem like a cheaper option initially, they can end up costing you more in the long run. Many DIY projects fail prematurely, leading to peeling, damage, and the need for costly repairs.

If the floor isn’t prepared properly, you may need to pay for additional prep work to remove the old coating before a professional can install a durable finish. This means you’re paying three times: once for the DIY kit, once for floor preparation and coating removal, and again for professional installation. To avoid the hassle, future repairs, and potential damage, investing in professional installation is often the smarter and more cost-effective choice.

Epoxy is a durable coating that, when applied correctly, can last for decades. However, many issues that cause peeling can be avoided with the right preparation and attention to detail. Here are some common reasons why your new epoxy floor might be peeling:

Choosing the cheaper DIY route or cheaper install may seem like a good idea at first, but it can cost you twice as much in the long run. You’ll end up paying for the initial kit, additional prep work, and professional installation when the DIY approach fails. Investing in proper preparation and a quality installation from the start will save you time, money, and frustration.

Excerpt -Morbi malesuada venenatis urna ac eleifend. Ut in laoreet est, et molestie felis. Pellentesque vitae nibh luctus, efficitur nunc vel, aliquet nisi. Nam non lacinia ligula. Ut eget venenatis eros. Nunc non mattis massa. Duis in euismod ex.

Excerpt -Morbi malesuada venenatis urna ac eleifend. Ut in laoreet est, et molestie felis. Pellentesque vitae nibh luctus, efficitur nunc vel, aliquet nisi. Nam non lacinia ligula. Ut eget venenatis eros. Nunc non mattis massa. Duis in euismod ex.